We are Manufacturer, Supplier, Exporter of Flush Bottom Valves, Flush Bottom Ball Valves from Mumbai, Maharashtra, India.

M1PCFFESIFBV

1 One Piece Cavity Filled Flange End Step In Flush Bottom Valves

| Mounting Interface | ISO 5211 |

| MOC of the Body | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) |

| Trim | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) |

| Seat / Cavity Filler | PTFE, RPTFE, CFT, Metal (Special on request) |

| Size | 1½” X 1” To 6” X 4” |

| Rating | 150#, 300# |

M1PCFSIJFBV

1 One Piece Cavity Filled Step In Jacketed Flush Bottom Valves

| Mounting Interface | MOC of the Body | Trim | Seat / Cavity Filler | Size | Rating |

| ISO 5211 | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) | PTFE, RPTFE, CFT, Metal (Special on request) | 1½” X 1” To 6” X 4” | 150# 300# |

M1PCFFFRTDFBV

1 One Piece Cavity Filled Flat Face Flush Bottom Valves With RTD Provision

| Mounting Interface | MOC of the Body | Trim | Seat / Cavity Filler | Size | Rating |

| ISO 5211 | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) | PTFE, RPTFE, CFT, Metal (Special on request) | 1½” X 1” To 6” X 4” | 150# 300# |

M3PCFWFFBV

3 Three Piece Cavity Filled Weldable Flange End Flush Bottom Valves

| Mounting Interface | MOC of the Body | Trim | Seat / Cavity Filler | Size | Rating |

| ISO 5211 | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) | PTFE, RPTFE, CFT, Metal (Special on request) | 1 To 4” | 150# |

M2PCFNFBV

2 Two Piece Cavity Filled Nauta Flush Bottom Valves

| Mounting Interface | MOC of the Body | Trim | Seat / Cavity Filler | Size | Rating |

| ISO 5211 | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) | PTFE, RPTFE, CFT, Metal (Special on request) | 8” X 6” To 14” X 12” | 150# |

M2PCFDRFBV (SIZE TO SIZE)

2 Two Piece Cavity Filled Direct Replacement Flush Bottom Valves

| Mounting Interface | MOC of the Body | Trim | Seat / Cavity Filler | Size | Rating |

| ISO 5211 | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) | PTFE, RPTFE, CFT, Metal (Special on request) | 1 To 4” | 150# |

M3PCFFEFBV

3 Three Piece Cavity Filled Flange End Flush Bottom Valves

| Mounting Interface | MOC of the Body | Trim | Seat / Cavity Filler | Size | Rating |

| ISO 5211 | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) | PTFE, RPTFE, CFT, Metal (Special on request) | 1½” X 1” To 6” X 4” | 150# |

M1PNCTBFBV

1 One Piece Non Cavity Filled Tank Bottom Valves

| Mounting Interface | ISO 5211 |

| MOC of the Body | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) |

| Trim | CF8, CF8M, CF3, CF3M, Hastalloy (Special on request) |

| Seat / Cavity Filler | PTFE, RPTFE, CFT, Metal (Special on request) |

| Size | 1½” X 1” To 6” X 4” |

| Rating | 150#, 300# |

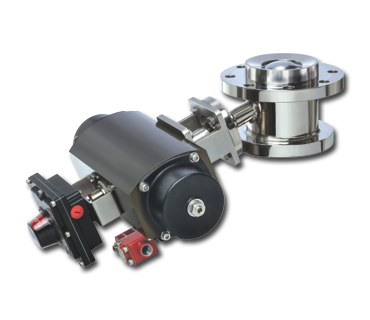

Features

- The valve is compact Ball type designed to open directly in the tank for 100% flushing to the inner surface of tank, reactor. Hence avoiding un-mixed cold zone stagnate pocket which is carefully profiled to fit tank bottom

- Cavity filled with PTFE or application suitable cavity filler to prevents fluid entrapment leading to contamination, hazards and production damage.

- Quarter-Turn operation Flush Bottom Valve has zero gland infiltration ensuring zero gland retention and zero gland restriction flushing and low energy quick response flushing.

- Valve - Actuator Mounting pad interface is designed to ISO 5211.

- Flush Bottom Tank Valve is an efficient, dependable perfect investment for trouble free fit and forget flushing performance.

- Flush Bottom Tank Valve is an efficient, dependable perfect investment for trouble free fit and forget flushing performance.

- Full-Port size segmented ball and cavity filled type flush bottom valve eradicates all internal pockets and puddling of condensate or biological fluid in the ball or the valve internal hence leaving no room for bacteria formation, growth and contamination.

Advantage

- The MPPL Flush Bottom Valves by virtue are ultimate in sealing compared to any other type of flush bottom valves for vaccum holding tanks and process.

- The MPPL Flush Bottom Valve supports in providing zero cavity internals enhancing the sealing to the tune of vacuum, ensured for life of the Flush Bottom Valve, as internals are not allowed to be damaged since there is no space for entrapment which normally causes damage to the ball and the seat. These Flush Bottom Valves are ideal for Hydrogenators.

- Tight shut-off and vaccum ensured.

- The MPPL Flush Bottom Valve gland is isolated from the flow by The valve cavity filler i. e. Gland sanitation and GMP4 Validation ensured.

- The MPPL Flush Bottom Valve supports and ensure clean internals by virtne of its segmented ball and zero cavity arrangement, achieving zero hold up (zero retention) in the cavity and internal of the valve body

- MPPL Flush Bottom Valves incorporates segmented ball, which ensure zero hold up when valve shuts, the material totally flushed into the drain / discharge holding no material in the I/D of the Ball.

- MPPL Flush Bottom Valve close into the tank bottom disc end leaving no space nor material un-churned during agitation which qualifies the validation of GMP4.

- With MPPL Flush Bottom Valve the agitator can be located just clear off the disc ends which ensure 100% thorough close to the disc-end for thorough mixture

- With MPPL Flush Bottom Valve the agitation time is reduced since the agitator is not away from the disc-end taking less time than other type of flush bottom valves which need clearance in the disc-end area. Hence the reaction mass in the bottom will not be mixed to that level as in the middle of the reactor.

- Online Sanitation - The MPPL Flush Bottom Valve can be operated couple of times on-line during CIP. SIP and WIP. hence does not need dismantling of the valve from the reactor losing valuable production time